Petrochemistry is in our DNA. Pictured above is Ján Madar (far right), the father of Ivan Madar, and his colleagues at the Faculty of Chemical Technology in 1951

-

1996

-

2000 - 2003

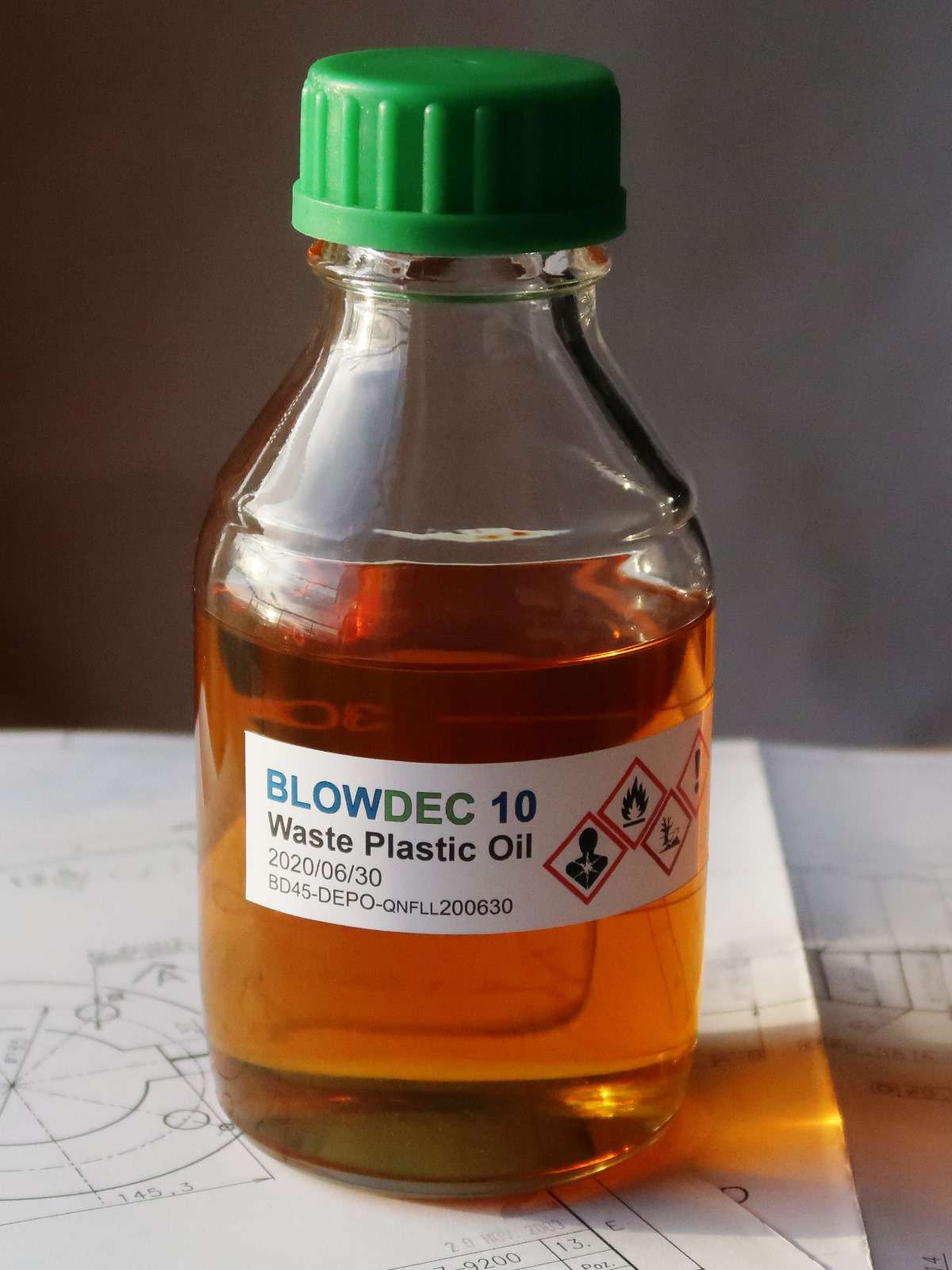

R&D Operation site is established for BlowDec® with a 45 kW reactor unit near Bratislava, Slovakia. Tests were gradually carried out with different types of real and simulated waste materials. At the same time, with the ongoing tests, the technological equipment was further innovated and optimised with modifications applied to correct inefficiencies. Our findings have been published in 2003 in Petroleum & Coal Paper, today available at ResearchGate.

-

2014 - 2019

BlowDec® is utilised for Waste Oil processing in Czech Republic